The Local Market Goes Global

Customer Profile

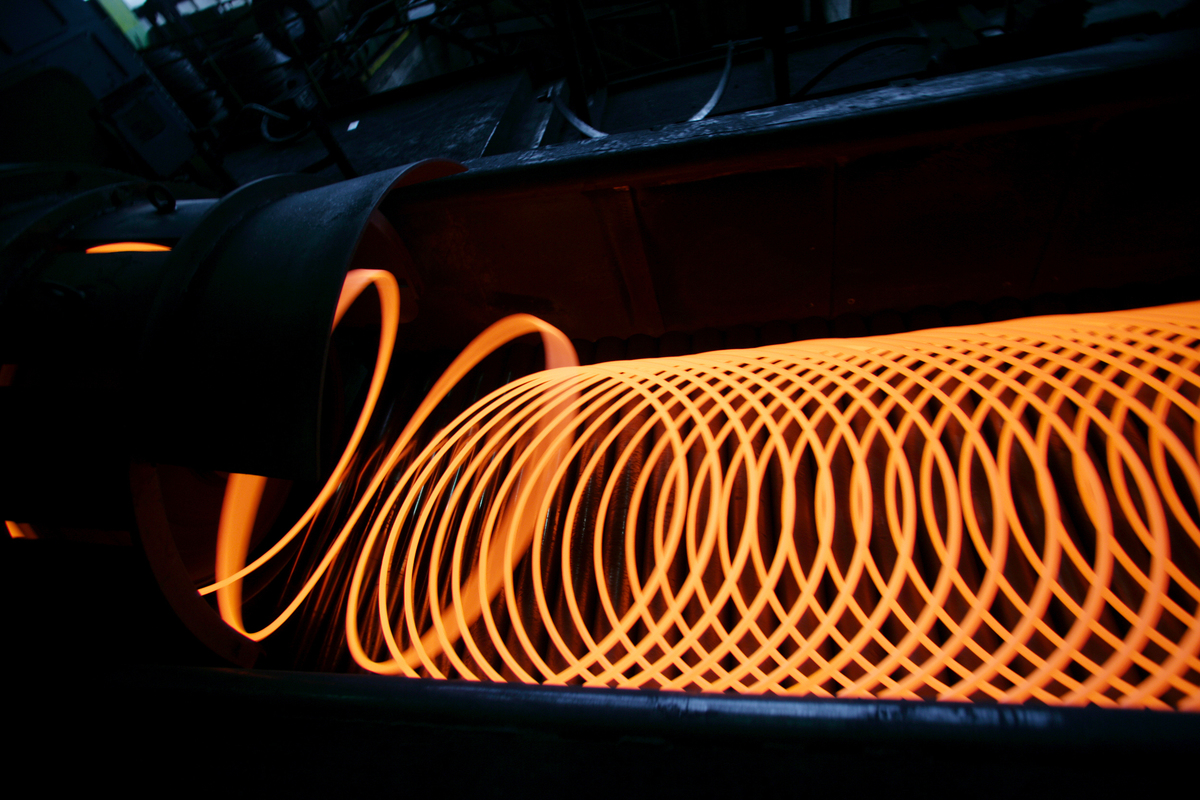

voestalpine is a worldwide leading technology and industrial goods corporation, combining competences in materials and processing. The global group has over 500 affiliates and offices in more than 50 countries on all five continents. With their high-quality product and system solutions from steel and other metals, the group is among the leading partners in the European automobile and household appliance industries, as well as the global oil and gas industry.

It employs 48,500 employees worldwide, who also hold a 14.5% stake in the company. The philosophy of the Austrian corporation voestalpine AG is “as decentralized as possible, as centralized as necessary”. This also applies to procurement, which is independently organized for each location. This makes it flexible and keeps it close to local needs. However, prior to the new project, there was still potential for savings that could be realized by acting together. To achieve this, procurement found a way to harmonize global strategic procurement processes.

Challenge

The high tech leader in steel production and processing is made up of 500 specialized, flexible entities acting independently across 50 countries on 5 continents. In recent years, voestalpine has positioned and developed a corporate procurement organization. The goals of the organization were, and still are, the improvement of joint cooperation and concentration of management.

In contrast, individual corporate entities are responsible for operational procurement. It was necessary to find a way to realize the great potential of the corporation despite the decentralized operation. The voestalpine group purchases everything needed for the production and further processing of steel: from raw materials, such as coal and iron, through machinery to furnaces, presses and punch presses, to auxiliary and process materials, like technical gases, natural gas and electricity. Each local procurement organization is also responsible for buying classic MRO products, such as tools, safety and sanitary articles, as well as services for construction, logistics and IT. Not every subsidiary needs the same material, but not even orders for office supplies were organized jointly. Due to everyday business, buyers had too little time to exchange information or coordinate better with colleagues. The decentralized organizational structure made this situation challenging for procurement.

Solution

The supplier management solution currently being rolled out in the corporation is providing the necessary transparency to coordinate better in the future. The introduction of the technology will harmonize global procurement processes and standardize them. There was also unused savings potential lying dormant in the different, sometimes unstructured processes in the corporation. Uniform and automatic processes will make the everyday business of a total of 400 employees across the procurement organizations easier and more efficient. The goal was a uniform supplier database to exchange data, such as certificates. All tenders will become transparent within the voestalpine group. This will help the company to tender together and profit from bundling effects. The local market will become global. A uniform scorecard system to rate shared suppliers was also planned. The local ERP systems of the different entities (mostly SAP systems) will remain untouched, while also being compatible with the new SRM solution, so that no data gets lost.

Overview Across the Corporation

Despite initial teething troubles, the newly-achieved transparency across all supplier data and current tenders in the corporation for all integrated parts of the business is a benefit. At the click of the mouse, buyers can inform themselves about global suppliers of a particular category including certificates and ratings. If an entity has a new purchase requisition, buyers only need look into the shared system to find the right supplier. Pooling demand from different corporate entities into joint orders leads to better prices. Smaller locations can benefit from better payment and delivery conditions if another entity has already negotiated on behalf of the corporation. JAGGAER provides all the relevant information to Procurement and the departments with which it works. It is no longer necessary to look separately into the local ERP systems. Everyone with access to the portal can see everything. Even though processes are standardized, JAGGAER can take the specificities of certain industries and categories into account. For example, supplier scorecards do not always use the same criteria, but the result of a rating can be understood across the corporation due to uniform classification.

The Local Market Goes Global

The standardization of global and strategic procurement processes within the decentralized organizational structure has reaped rewards. The buyers benefit from the reduction of workload everyday. In the future, voestalpine would like to handle 100% of their purchasing processes over JAGGAER, relieving even more workload from procurement. The office in Linz is already using all ordered modules. The other offices are being connected step-by-step. More than 1,000 tenders have been processed in the software so far and 2,000 suppliers are registered on the platform – an upward trend. Access to all supplier data in the corporation opens up completely new purchasing opportunities in international markets for the procurement organizations.

Bottom-Line Results

- Central SRM system for better supplier management

- Globally uniform supplier database

- Transparency into data and tenders across the corporation

- Standardization and harmonization of procurement processes

- Active and simple data exchange of certificates, D&B ratings, etc.

- Local ERP systems remain untouched with multi-ERP integrations